Aluminum is one of the most versatile materials available, thanks to its ability to be finished in a variety of ways to enhance its appearance, durability, and functionality. Each type of finish is suited for specific applications, making it important to understand your options before starting a project. Here’s a closer look at five popular aluminum finishes and when to use them.

1. Anodized Aluminum

Anodized aluminum is a finish that strengthens the material’s natural oxide layer, providing exceptional durability and corrosion resistance. It’s not just practical—it also allows for vibrant colors and a sleek, modern appearance. This finish is ideal for architectural projects like window frames and curtain walls, as well as consumer products such as electronics and cookware. Thanks to its resistance to weather and wear, it’s a top choice for outdoor applications.

2. Brushed Aluminum

Brushed aluminum stands out for its distinctive matte texture, created by treating the surface with fine lines that reduce reflectivity while maintaining a metallic shine. This finish is often used in interior design for elements like backsplashes or wall panels, offering a clean, modern aesthetic. You’ll also find it in products like kitchen appliances and automotive trim, where a subtle yet stylish look is desired.

3. Polished Aluminum

With its highly reflective, mirror-like surface, polished aluminum is all about elegance and visual impact. This finish is achieved through a meticulous buffing process, making it perfect for decorative applications, high-end furniture, and automotive or marine accents. Polished aluminum also works well for projects requiring light reflection, such as in lighting fixtures or solar energy installations.

4. Painted Aluminum

Painted aluminum opens the door to endless design possibilities. Coated with paint or powder, it provides vibrant colors and added protection against the elements. Commonly used in exterior building cladding, it ensures durability and visual appeal. It’s also a favorite for custom signage and branding, where specific colors can be matched for cohesive aesthetics. Whether for construction, advertising, or industrial purposes, painted aluminum offers a winning combination of form and function.

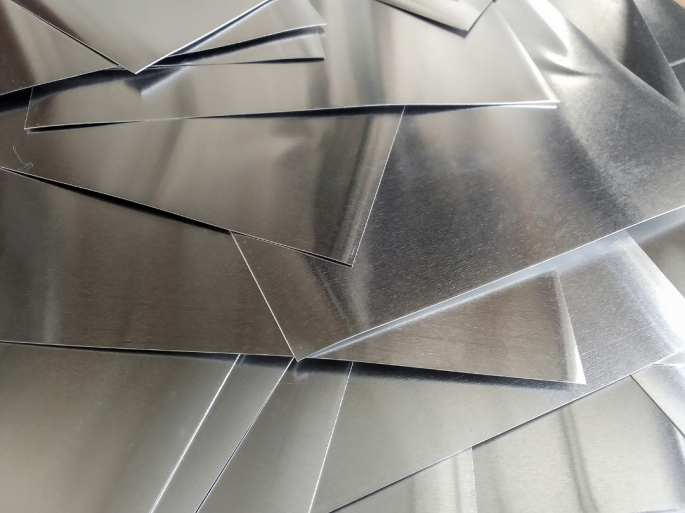

5. Mill Finish Aluminum

Mill finish aluminum is raw, untreated material straight from the production process. While it doesn’t boast the enhancements of other finishes, its versatility and cost-effectiveness make it a practical choice for industrial and mechanical applications. It’s often selected for projects where the material will be further processed, such as welding, cutting, or bending. Though less visually refined, mill finish aluminum is highly functional and economical.

Making the Right Choice

The finish you choose for your aluminum project depends on your specific goals. If you’re prioritizing durability and color, anodized or painted aluminum is a smart choice. For sleek and sophisticated aesthetics, brushed or polished aluminum is ideal. When budget and versatility are the main concerns, mill finish aluminum delivers reliable performance.

At Wrisco, we’re here to help you find the perfect aluminum finish for your project. Our extensive selection and expertise ensure that your material not only meets your needs but exceeds your expectations.

Ready to Get Started?

Contact Wrisco today to explore our aluminum finishes and discover how we can elevate your next project with the perfect materials.