Aluminum Products

Aluminum & Steel Coil Processing

Here at WIELAND-WRISCO INDUSTRIES INC., we understand how important it is to get your aluminum sheeting order out to you and your team in a quick an efficient manner, while also meeting your dimensional and tolerance needs. That’s why we utilize Cut-to-Length Coil Metal Processing at all four of our divisions. With our CTL coil processing equipment, we’re able to simplify the process of sizing and cutting your order without ever having to stop, drastically decreasing lead times. Our CTL machines are capable of working on aluminum blanks, steel, anodized aluminum, and a number of other alloys and metals.

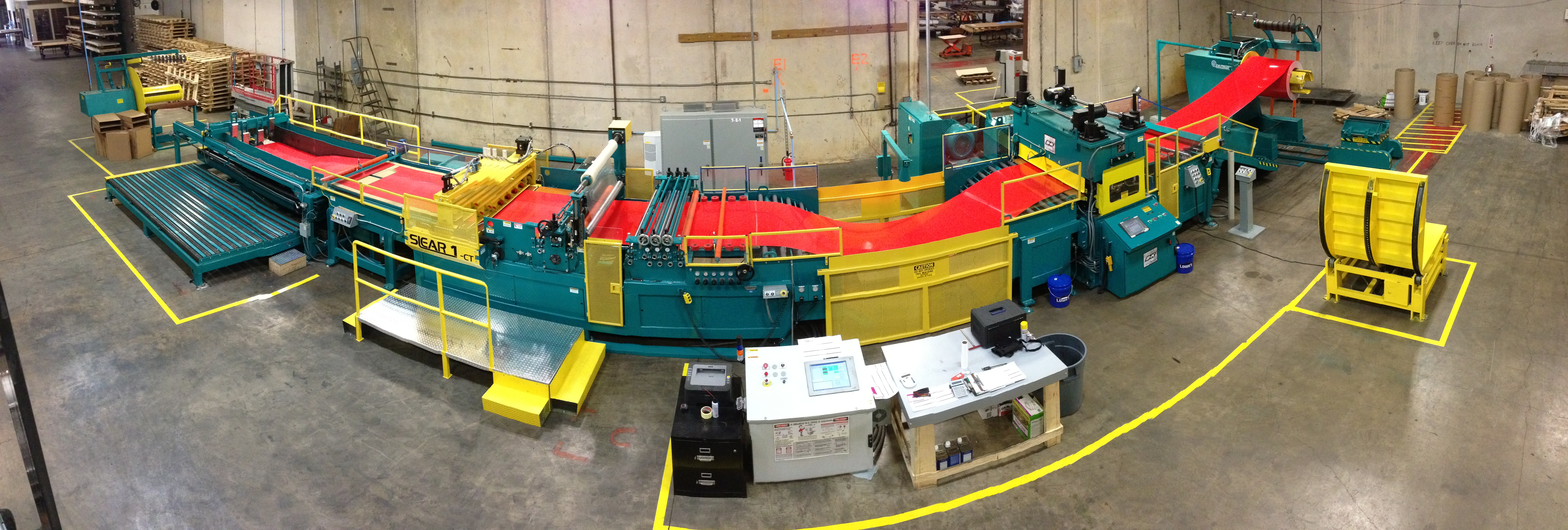

Our Cut-to-Length equipment lineup includes Mestek Machinery’s Iowa Slear 1 and Slear 2 with B & K Leveler located in Atlanta and the Mestek Machinery Iowa Slear 1 with B & K Leveler housed in Dallas. Teamed with five other Cut-to-Length and Slitting Lines throughout our Divisions, Wieland-Wrisco can sheet, blank, slit, shear, level and recoil with extremely tight tolerances up to 60″ wide coil in gauges .018 through .125 in aluminum and 48″ wide coil in 24 gauge steel. Custom slit coils and cut-to-length pieces are available upon request.

Benefits of Coil Processing

- Decreased Lead Times: When you’ve got a job that has a tight deadline and little to no wiggle room, you need a sheet metal manufacturer and supplier that understands your project’s goals as good as you do. With our coil processing CTL line, we’re able to meet your project requirements, and needs. Our CTL equipment allows us to drastically decrease lead times on all sheeting needs, meeting your goals and allowing your team to focus on the job at hand.

- Precision Cutting & Sizing: No two jobs are the same, and each one has its own specifications and size requirements. With our CTL machines and team, we can guarantee perfection. They’re able to set a predetermined size while utilizing our CTL equipment and watch as they trim sheets down to exact sizes. No jagged edges, no dented sheets, no mistakes.

- Custom Solutions: Whether it’s painted, anodized, 70% PVDF, mill finish, aluminum tread brite or painted steel, we’re able to offer it all, thanks to our coil processing system! Interested in learning more about our coil processing, or looking to place an order? Simply contact us today and one of our team members will be happy to assist!